UV driven AOP modular reactors (UV-AOP-C and UV-AOP-T)

Unlike of other technologies available on the market, they are able to simultaneously remove chemical contaminants and microorganisms (disinfection). They can be used in:

- tertiary (disinfection) and quaternary (removal of contaminants of emerging concern (CECs) treatment of urban wastewater to be disposed into the environment or reused;

- pre-treatment of industrial wastewater (before the biological process) to make it more biodegradable;

- post-treatment of industrial wastewater (after the biological process) to remove specific pollutants not in compliance with the respective regulatory limits;

- treatment of other aqueous matrices (e.g., drinking water, grey water, rainwater, etc.) to remove specific contaminants.

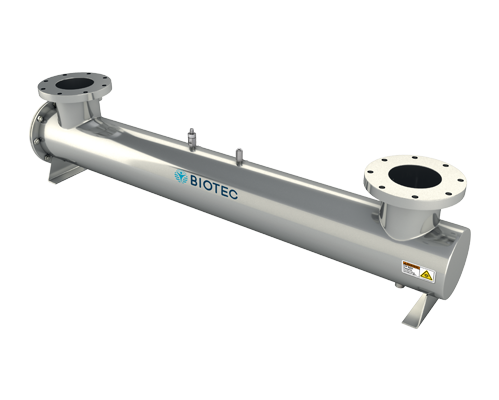

These modular reactors are available in channel (UV-AOP-C) and tubular (UV-AOP-T) configurations, respectively.

Modular reactor available in tubular cofiguration (UV-AOP-T)

Advantages compared to consolidated processes/technologies: no formation of regulated disinfection by-products (unlike of chlorine, ozone and chlorine dioxide), higher efficiency in terms of CECs removal compared to conventional disinfection processes (namely, chlorination, peracetic acid, UV-C radiation), higher disinfection efficiency compared to adsorption process.

Solar driven AOP (S-AOP)

If the flow rate to be treated is sufficiently small, the solar driven AOP solution can be used, with evident benefits in terms of environmental and energy sustainability (pilot plant in the photo 3).

This solution can be implemented as:

- tertiary (disinfection) and quaternary (removal of contaminants of emerging concern) treatment of urban wastewater to be disposed into the environment or reused;

- post-treatment of industrial wastewater (after the biological process) to remove specific pollutants not in compliance with the respective regulatory limits;

- treatment of other aqueous matrices (e.g., drinking water, grey water, rainwater, etc.) to remove specific contaminants.

Comparison among processes for tertiary and quaternary urban wastewater treatment

Bacterial inactivation |

Formation of DBPs |

CECs removal |

Safety |

Investment costs |

Management costs (Energy costs) |

|

Free chlorine |

+++ |

+++ |

+ |

++ |

+ |

+ (+) |

ClO2 |

+++ |

+++ |

+ |

+ |

+++ |

++ (++) |

O3 |

+++ |

+++ |

+++ |

++ |

+++ |

+++ (+++) |

PAA |

+++ |

– |

+ |

++ |

+ |

++ (+) |

UV-C |

+++ |

– |

+ |

++ |

+++ |

++ (+++) |

UV-AOP |

+++ |

– |

+++ |

++ |

+++ |

++ (+++) |

Solar-AOP |

+++ |

– |

+++ |

+++ |

++ |

+ (+) |

Membranes |

++ |

– |

++ |

+++ |

+++ |

+++ (+++) |

Adsorption |

+ |

– |

+++ |

+++ |

+++ |

+++ (+) |

+= low; ++= medium; +++ = high;

AOP= advanced oxidation processes; CECs = contaminants of emerging concern; DBPs= disinfection by-products; Free chlorine= Cl2, NOCl, Ca(OCl)2; PAA= peracetic acid.

Solar AOP feasible only for small wastewater treatment plants

UV driven AOP/separation modular reactor (UV-AOP-S)

This system couples two technologies, one based on UV driven AOPs and the other on a separation process to remove arsenic from drinking water.

Advantages: Unlike conventional oxidation processes (chlorine, ozone and chlorine dioxide) it does not form regulated oxidation/disinfection byproducts (trihalomethanes, bromates and chlorites, respectively).

Grey water treatment module (GWT)

It is an effective technology for grey water treatment and removing surfactants and COD.

In case of need (disinfection or more thorough removal of some pollutants) it can be coupled with a UV disinfection or UV driven AOP unit, respectively.